Material Selection

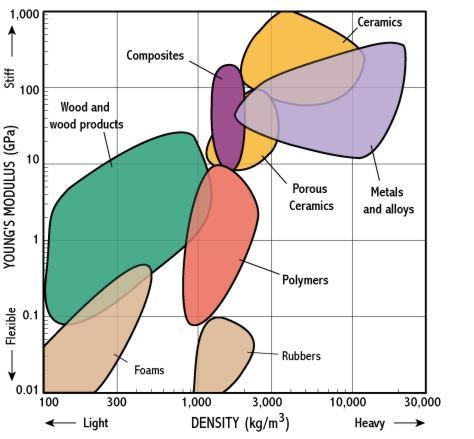

Materials Selection is the process of identifying the best material to make your product from. It is a key step in product development where the attributes of a particular metal alloy, plastic, etc. are weighed against cost, performance and manufacturability. The objective in any consumer product is to select materials that minimize cost but maintain the performance goals. Having knowledge of the different materials and their properties is critical in optimizing your product. For example, if your product will be subject to high temperatures and high stress, you need a material that can handle both – such as a nickel based super-alloy or a ceramic. If this product must also have good toughness to avoid brittle fracture then the use of a ceramic may be a poor choice. This is just one simple example of what can be a complex process to narrow the field of materials choices for your project.

We have helped dozens of companies optimize their products through a comprehensive evaluation and recommendation process that consists of:

- Evaluation of current materials attributes and limitations

- Identification of alternative candidate materials based on operating environment, cost and manufacturing constraints.

- Recommendation of several candidate materials.

- Evaluate material change through comprehensive product testing*

*This step is done in partnership with manufacturing facility

To read more about Materials Selection and Examples of our Work please click here.